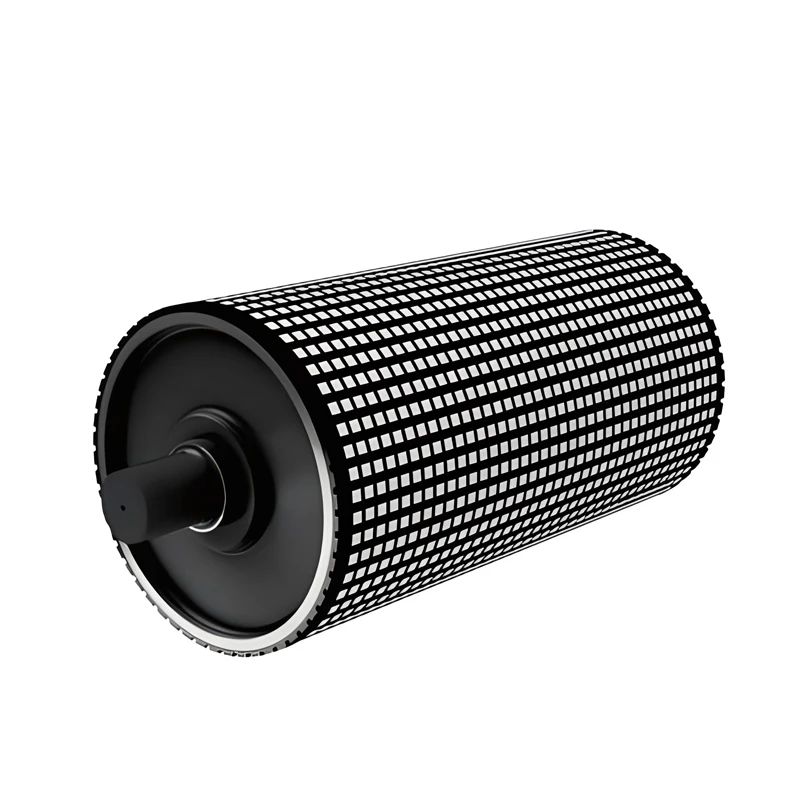

Driving Efficiency: The Imperative Role of a Modern Conveyor Roller Manufacturer In the backbone of industrial automation and material handling, the role of a proficient conveyor roller manufacturer is paramount. These critical components facilitate the smooth, reliable, and energy-efficient movement of goods across diverse sectors, from mining and metallurgy to logistics and food processing. As a specialized conveyor roller manufacturer , we understand that optimal performance hinges on precision engineering, robust materials, and rigorous quality control. This detailed exploration delves into the technical intricacies, application versatility, and strategic advantages offered by advanced conveyor roller systems, specifically highlighting our expertise in manufacturing solutions tailored for challenging environments, including the specialized Explosion Proof Conveyor Drum. The landscape of material handling is constantly evolving, driven by demands for increased throughput, reduced operational costs, and enhanced safety. A leading conveyor roller manufacturer must continually innovate, integrating cutting-edge technologies and materials to meet these evolving industrial requirements. Our focus extends beyond merely producing components; we aim to provide comprehensive solutions that elevate the performance and longevity of entire conveyor systems, aligning with the needs of every modern conveyor belt manufacturer and conveyor manufacturer . Industry Trends: Navigating the Future of Material Handling The conveyor industry is witnessing a transformative shift, driven by several key trends that influence product design and manufacturing processes for a conveyor roller manufacturer : Energy Efficiency: With rising energy costs and environmental concerns, there is a growing demand for rollers that minimize friction and energy consumption. Innovations in bearing technology and lightweight materials are crucial. Smart Conveyor Systems (IoT Integration): The integration of sensors and IoT devices into conveyor rollers allows for real-time monitoring of performance, temperature, and wear, enabling predictive maintenance and preventing costly downtime. Advanced Materials: Development of rollers made from specialized polymers, ceramics, and composite materials offers enhanced resistance to wear, corrosion, and extreme temperatures, extending service life in harsh environments. Sustainability: Manufacturers are increasingly focused on producing recyclable components and adopting greener manufacturing processes to reduce environmental impact. Customization and Modularity: The need for highly specialized conveyor systems means manufacturers must offer extensive customization options, from specific dimensions and coatings to unique operational requirements. These trends underscore the importance of continuous R&D and a flexible manufacturing approach to remain competitive and deliver value to industries relying on robust material handling solutions. Precision Engineering: The Manufacturing Process of Conveyor Rollers The production of high-quality conveyor rollers involves a meticulous, multi-stage process designed to ensure durability, precision, and optimal performance under various operational stresses. As an experienced conveyor roller manufacturer , our process integrates advanced technology with stringent quality controls. Process Flow Overview: Material Selection & Preparation: We utilize high-grade materials such as cold-rolled steel (e.g., Q235, S235JR), stainless steel (e.g., SS304, SS316 for corrosion resistance), PVC, and HDPE. For specialized applications like our Explosion Proof Conveyor Drum, robust, anti-static, and spark-resistant materials are chosen to prevent ignition risks. Materials undergo strict inspection for chemical composition and mechanical properties. Tube Cutting & Machining: Precision CNC machines cut the roller tubes to exact lengths. Ends are then machined to ensure perfect concentricity and perpendicularity, critical for balanced rotation and minimal run-out. Shaft Manufacturing: High-tensile steel shafts are precisely machined, often through forging or cold-drawn processes, to ensure strength and accuracy. Bearing seats are machined to tight tolerances to accommodate bearings correctly. Bearing and Seal Installation: High-quality bearings (e.g., deep groove ball bearings, tapered roller bearings) are selected based on load capacity and speed requirements. Multi-labyrinth seals, vital for protecting bearings from dust and moisture ingress, are meticulously installed. For explosion-proof applications, specialized sealed bearings and non-sparking seals are employed. End Cap & Housing Assembly: Stamped or cast end caps are welded to the roller tube using automated welding processes (e.g., MIG/MAG welding) to ensure strong, consistent seams. The shaft assembly is then integrated into the roller housing. Surface Treatment: Depending on the application, rollers undergo various surface treatments. These include galvanizing for corrosion resistance, powder coating for enhanced durability and aesthetics, or rubber lagging for increased friction and belt protection. Quality Control & Testing: Each roller undergoes rigorous testing. This includes dimensional accuracy checks, run-out tests, rotational resistance measurement, static and dynamic load testing, and seal effectiveness verification. We adhere to international standards such as ISO 9001 for quality management, ANSI/CEMA (Conveyor Equipment Manufacturers Association) standards for design and performance, and ATEX/IECEx certifications for explosion-proof products, ensuring a typical service life of 30,000 to 50,000 hours under rated conditions. Packaging & Dispatch: Finished rollers are carefully packaged to prevent damage during transit, ready for deployment in target industries such as petrochemical, metallurgy, mining, power generation, and water supply & drainage, where advantages like energy saving, corrosion resistance, and reduced maintenance are critical. This comprehensive manufacturing approach ensures that every roller leaving our facility meets the highest standards of quality and performance, contributing to the overall efficiency and safety of material handling operations. Key Technical Parameters for Explosion Proof Conveyor Drums Our Explosion Proof Conveyor Drum is engineered to operate safely and reliably in hazardous environments where explosive gases, dust, or fibers may be present. These drums are designed with advanced features to mitigate ignition risks, ensuring compliance with international safety standards like ATEX and IECEx. The following table outlines typical specifications: Typical Specifications: Explosion Proof Conveyor Drum Parameter Specification Notes / Compliance Diameter Range Ø110mm to Ø800mm (Customizable) Designed for various belt widths Face Length (L) 400mm to 2000mm (Customizable) Matches conveyor belt width Shaft Diameter Ø30mm to Ø160mm (Customizable) High-tensile steel, precise machining Material Steel (Q235/S235JR), Stainless Steel (SS304/SS316) with specialized anti-static coatings or lagging. Ensures non-sparking and corrosion resistance IP Rating IP66/IP67 (Dust & Water Jet/Immersion Protection) Critical for environmental protection Explosion Protection Class Ex d IIC T4 Gb / Ex tb IIIC T135°C Db ATEX Directive 2014/34/EU, IECEx certified Bearing Type Self-aligning spherical roller bearings, deep groove ball bearings (sealed) Low friction, long service life, specialized seals Load Capacity Up to 50kN per roller (depending on size and design) Designed for heavy-duty applications Service Life ≥ 50,000 hours (under ideal operating conditions) Minimizes replacement and maintenance costs These technical specifications are critical for engineers and procurement specialists when selecting reliable and compliant components for operations in hazardous and demanding industrial environments. Application Scenarios for Conveyor Rollers The versatility of conveyor rollers makes them indispensable across a wide array of industries. Our products, particularly the Explosion Proof Conveyor Drum, find critical application in: Mining & Quarrying: Handling abrasive materials like coal, iron ore, and aggregates. Heavy-duty rollers with robust seals are essential for these dusty, harsh environments. Petrochemical & Chemical Plants: Transporting raw materials and finished products in environments with explosive gases or corrosive chemicals. Explosion-proof and chemical-resistant rollers are paramount for safety and longevity. Power Generation: Conveying coal, ash, and other bulk materials in power plants. Durability and high load capacity are key. Cement & Construction: Moving cement, clinker, and aggregates. Rollers must withstand heavy impact and abrasive wear. Food & Pharmaceutical: Requiring hygienic, corrosion-resistant, and easily cleanable rollers (often stainless steel or food-grade polymers) to prevent contamination. Logistics & Warehousing: High-speed and quiet operation rollers for package handling and sorting systems. Energy efficiency is a significant advantage here. Port & Terminal Operations: For loading and unloading bulk cargo, requiring large-diameter, heavy-duty rollers capable of operating in corrosive marine environments. Each scenario demands specific roller characteristics, highlighting the need for a conveyor roller manufacturer that can provide tailored solutions. Technical Advantages of Our Conveyor Rollers Our commitment as a leading conveyor roller manufacturer is reflected in the advanced technical features and inherent advantages of our products: Exceptional Durability: Engineered with high-strength materials and superior welding techniques, our rollers withstand extreme loads and abrasive conditions, ensuring extended operational life and reduced replacement frequency. Low Rolling Resistance: Precision-machined components and high-quality bearings significantly reduce friction, leading to lower energy consumption for the conveyor system. This translates directly into substantial energy savings and reduced operational costs. Advanced Sealing Systems: Multi-labyrinth sealing systems provide robust protection against dust, dirt, and moisture ingress, safeguarding the bearings and maintaining smooth operation, especially in harsh environments. Minimal Maintenance Requirements: The design emphasis on longevity and protection means our rollers require less frequent inspection and lubrication, minimizing downtime and maintenance expenditure. Precision Manufacturing: Strict adherence to tight manufacturing tolerances ensures excellent concentricity and minimal run-out, which reduces vibration, noise, and wear on the conveyor belt itself. Corrosion and Chemical Resistance: Options for stainless steel construction and specialized coatings provide superior resistance to corrosive agents, making them suitable for chemical plants, coastal operations, and food processing. Explosion-Proof Safety (for specialized products): Our Explosion Proof Conveyor Drums feature certified designs that prevent ignition of explosive atmospheres, incorporating materials with low surface resistance, intrinsically safe components, and rigorous thermal management, meeting global ATEX/IECEx standards. Optimized Load Distribution: Robust shaft designs and precisely fitted bearings ensure uniform load distribution, preventing premature wear and extending the life of both the roller and the conveyor belt. These advantages collectively contribute to a higher return on investment by enhancing operational efficiency, reducing safety risks, and extending the overall lifespan of material handling systems. Vendor Comparison: Choosing the Right Conveyor Roller Manufacturer Selecting the appropriate conveyor roller manufacturer is a strategic decision that impacts operational efficiency, safety, and long-term costs. A comparative analysis based on critical factors can guide this choice: Conveyor Roller Manufacturer Comparison Feature/Criteria HG Conveyor Belt (Our Expertise) Vendor B (Competitor) Vendor C (Standard Offerings) Customization Capability Extensive; material, size, coating, ATEX/IECEx compliance. Moderate; standard modifications. Limited; off-the-shelf products. Certifications & Compliance ISO 9001, ATEX/IECEx (for specialized drums), CEMA/DIN standards. ISO 9001, some regional standards. Basic ISO, often self-certified. Material Quality & Sourcing Premium-grade steel, SS, advanced polymers; traceable sourcing. Good quality, mostly standard grades. Cost-effective materials, less rigorous inspection. R&D and Innovation High investment in new materials, energy efficiency, IoT integration. Moderate; focused on incremental improvements. Low; primary focus on production volume. Technical Support & Expertise Dedicated engineering support, application specialists. Standard technical support. Limited, mostly sales-driven. Price Point Competitive for value, higher for specialized products. Mid-range. Lower, basic product range. Warranty & After-Sales Comprehensive warranty, responsive global support. Standard warranty, regional support. Basic warranty, limited support. This comparison illustrates why partnering with a proven conveyor roller manufacturer offering advanced solutions and strong support is crucial for long-term operational success. Customized Solutions for Unique Industrial Demands Standard conveyor rollers often fall short in meeting the precise demands of specialized industrial environments. As a dedicated conveyor roller manufacturer , we excel in providing bespoke solutions engineered to exact client specifications. Our customization capabilities include: Material Adaptation: From ultra-high molecular weight polyethylene (UHMW-PE) for abrasive and sticky materials to specialized stainless steel alloys for extreme corrosion resistance or high temperatures. Dimensional Precision: Manufacturing rollers with specific diameters, lengths, and shaft configurations to perfectly fit existing conveyor structures or integrate into new, custom-designed systems. Surface Coatings & Lagging: Applying rubber lagging for enhanced friction and belt protection, ceramic coatings for extreme wear resistance, or anti-static treatments for hazardous areas. Bearing and Sealing Systems: Integrating specialized bearings (e.g., ceramic bearings for non-magnetic or high-temperature applications, self-aligning bearings) and advanced sealing systems tailored to combat specific contaminants (fine dust, moisture, chemicals). Environmental Adaptations: Designing rollers for operations in sub-zero temperatures, high humidity, or vacuum environments, ensuring reliable performance regardless of external conditions. Load and Speed Optimization: Engineering rollers to handle exceptionally heavy loads or operate at high speeds without compromising durability or safety. This focus on customization allows industries to optimize their material handling systems for maximum efficiency, safety, and longevity, reducing the total cost of ownership over the operational life cycle. Application Case Studies: Real-World Impact Our expertise as a conveyor roller manufacturer has translated into significant operational improvements for diverse clients: Case Study 1: Enhanced Safety in a Petrochemical Refining Facility A major petrochemical client faced significant safety challenges in their refining unit, where combustible gases and dust were present. Standard conveyor rollers posed an inherent ignition risk. We engineered and supplied a fleet of custom Explosion Proof Conveyor Drums (ATEX Zone 1 certified). These drums featured specialized anti-static rubber lagging, non-sparking materials, and sealed bearings with high IP ratings. The result was a dramatic improvement in operational safety, fully compliant with international explosive atmosphere regulations, reducing downtime related to safety inspections by 30% and eliminating previous spark-related incidents. Case Study 2: Extending Service Life in a Chilean Copper Mine A large open-pit copper mine in Chile struggled with premature roller failure due to extreme abrasion from crushed ore and harsh environmental conditions (high dust, temperature fluctuations). We provided heavy-duty troughing rollers with enhanced steel thickness, specially formulated ceramic lagging, and advanced multi-labyrinth seals designed for extreme dust protection. After implementation, the average service life of their conveyor rollers increased by over 75%, leading to a 20% reduction in maintenance costs and a substantial increase in overall conveyor uptime. Case Study 3: Energy Optimization in a Logistics Distribution Center A major e-commerce logistics hub sought to reduce its energy footprint while maintaining high-speed sorting capabilities. We supplied high-precision, low-friction rollers incorporating advanced bearing technology and lightweight composite materials. The implementation resulted in a measurable 12% reduction in the total energy consumption of their main conveyor lines, contributing to significant operational savings and supporting their corporate sustainability goals, without compromising throughput speed or reliability. Trust and Authority: Our Commitment to Excellence As a responsible conveyor roller manufacturer , we uphold the highest standards of quality, reliability, and customer service. Our commitment is underpinned by: Certifications: ISO 9001 certified for quality management systems, ensuring consistent product quality. Our Explosion Proof Conveyor Drums are independently tested and certified to ATEX and IECEx standards, affirming their safety in hazardous environments. Experience: With decades of experience in the material handling industry, we have a deep understanding of diverse application challenges and engineering solutions. Partnerships: We partner with leading raw material suppliers and technology providers to ensure our products incorporate the best available components and innovations. R&D Focus: Continuous investment in research and development ensures we remain at the forefront of conveyor roller technology, delivering superior performance and efficiency. Frequently Asked Questions (FAQ) Q: How do your explosion-proof rollers ensure safety? A: Our Explosion Proof Conveyor Drums are designed with intrinsic safety principles, using non-sparking materials, anti-static coatings, special sealed bearings, and thermal management to prevent excessive heat buildup. They undergo rigorous testing and are certified to international standards like ATEX and IECEx for operation in classified hazardous zones. Q: What is the typical lead time for custom conveyor rollers? A: Lead times vary depending on the complexity of customization and order volume. For standard products, lead time is typically 4-6 weeks. For highly customized solutions, it can range from 8-12 weeks. We provide accurate lead time estimates upon quote finalization. Q: What warranty do you offer on your products? A: We offer a standard warranty of 12-24 months on our conveyor rollers, covering manufacturing defects and material failures under normal operating conditions. Extended warranty options are available upon request for specific projects. Q: Do you provide installation support and after-sales service? A: While our rollers are designed for straightforward integration, we offer comprehensive technical support, including installation guidelines and troubleshooting assistance. Our after-sales service includes spare parts supply and expert consultation to ensure long-term operational excellence. Lead Time and Fulfillment Our advanced manufacturing facilities and efficient supply chain management enable us to provide competitive lead times. For standard roller configurations, production and fulfillment typically range from 4 to 6 weeks. For specialized or high-volume orders, a detailed production schedule will be provided, generally spanning 8 to 12 weeks. We prioritize clear communication throughout the order process to ensure timely delivery. Warranty and After-Sales Support We stand behind the quality and durability of our products. All conveyor rollers come with a comprehensive warranty against manufacturing defects, typically ranging from 12 to 24 months, depending on the product type and application. Our dedicated after-sales support team is readily available to provide technical assistance, answer queries, and facilitate any necessary service or spare parts requests. Our goal is to ensure the continuous and reliable operation of your conveyor systems. For more detailed information or to discuss your specific requirements, please contact our expert team. We are committed to being your reliable partner in material handling solutions. Conclusion The efficiency and safety of industrial operations are inextricably linked to the quality and reliability of their conveyor systems. As a leading conveyor roller manufacturer , our mission is to provide cutting-edge solutions, including highly specialized products like the Explosion Proof Conveyor Drum, that meet the rigorous demands of modern industries. Through continuous innovation, stringent quality control, and a deep understanding of application-specific challenges, we empower our clients to achieve unparalleled operational excellence and sustained productivity. References ISO. (n.d.). ISO 9001:2015 - Quality management systems - Requirements. Retrieved from iso.org CEMA. (n.d.). Conveyor Equipment Manufacturers Association. Retrieved from cemanet.org ATEX Directive 2014/34/EU. (n.d.). European Commission. Retrieved from ec.europa.eu IECEx Scheme. (n.d.). International Electrotechnical Commission. Retrieved from iecex.com Bulk Solids Handling: An Introduction to the Practice and Technology. (2018). Woodhead Publishing.